Outage Management from start to finish

Transparent actions and information flows between the control room, field crews and customers. Real-time data, the efficiency of operations and top-notch situational awareness thanks to quality systems and processes. That’s outage management in the MV (medium voltage) and HV (high voltage) networks at the electric utility Elenia, all aiming at great customer service.

Elenia is the second largest electricity DSO (distribution system operator) in Finland, supplying electricity to 425 000 homes and businesses, and covering over 100 municipalities vast across the center of the country. The usual fault causes are thunderstorms and risky trees falling on the power lines, and, as Elenia invests heavily on underground cabling, one common cause has become excavators when digging goes wrong.

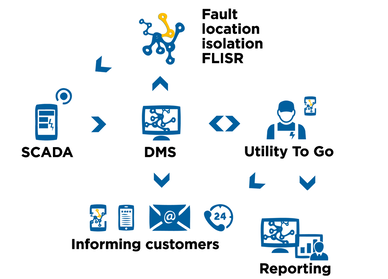

In its outage management, Elenia highlights the importance of transparency. The utility has put effort into developing both their processes and systems for ensuring that the customers are informed about a fault immediately, and both the control room and the field crews can follow up on how the situation evolves in real time. As the utility keeps fine-tuning its outage handling practices, there is less and less need for phone calls, and thanks to the modern mobile solution Utility To Go (or UTG, as known in the field), Elenia only needs a phone call from the field crews in the medium voltage cases when doing manual switchings, or when something exceptional happens. The mobile solution allows for the linemen to see all the needed information, helps in navigation, and can even show the locations of the field crews to the control room operators.

Teemu Suvela, Operations Engineer at Elenia, benefits from the high automation in the Elenia control room on a daily basis. He describes: “In case of a medium voltage or high voltage fault, the SCADA (supervisory control and data acquisition) system sends the breaker event to the DMS (distribution management system), where I then see the outage. It shows up on the outage list, and on the map, the topology shows the network parts behind the faulted feeder on white.”

In larger disturbances, the ongoing calculation helps the operator even further. “We can see the estimated KPIs by outage on the outage management list, and we can prioritize the faults by those calculations,” says Teemu, explaining: “So, for example, as we have operators who might not be that familiar with the entire network, they can only check the figures that the DMS is giving them on which faults to handle first.” To support that, the outages are color-coded in green, yellow, and red by duration. “After 6 hours, since it’s our customer promise to keep any outage shorter than that, the outage is shown in red. In major disturbances like bigger storms, the color-coding is really helpful,” Teemu concludes.

In the medium voltage network, the control room takes care of isolating the fault area with remote disconnectors. After, a field crew is dispatched with the information about the outage and the possible manual disconnectors they are to go to for further isolation.

The field crew can use their smartphones or tablets to see, for example, the real-time network topology and the fault area, and they can navigate to the place directly with their Utility To Go. “I prefer the navigation,” says Helmina Sioris, Electrician at Eltel Networks, a contractor for Elenia. She continues: “In the network information, you have the picture of the car and by tapping it, you can straight navigate with Google Maps. And the maps are really clear and easy, and you can, for example, choose the base you like to use, whether that be the satellite picture or just the basic map.”

Once at the manual disconnector, the field crew calls the control room for a permission to open it. Teemu explains: “This way, we find with the specific fault area with the field crew member, until there are no more disconnectors to open. The field crew can then lock and tag the disconnectors, and earth the fault area.” Next, the linemen start their work to find and repair the fault, informing the control room about their findings, the estimated time of restoration and the final fix as they go. Everything gets recorded in the DMS. After the fix, the control room authorizes the manual disconnectors to be closed and the electricity can be restored to the customers. The operator also ensures that the cause and location of the fault as well as the downtime calculations are correct in the records, and the DMS takes care of the reporting automatically, including the outage duration experienced by the customers and the outage KPIs for the utility.

During the outage management process - or especially at the beginning of the outage - the FLISR (fault location, isolation, and service restoration) and the additional automatic fault location system bring the utility even more added value.

Teemu describes: “When you are working alone at the night shifts, and there is a larger outage situation, say a thunderstorm at a small local area where many medium voltage feeders are tripped, the FLISR plays a big role because it can start to automatically isolate those feeders.” The automation allows the operator to focus on sending the field crews to the right location while the system takes care of the isolation at the same time. In case of short-circuit faults, the automatic fault location helps even further. Teemu continues: “When a breaker trips, the SCADA system gets a fault reactance from the substation and sends it to the DMS. The DMS, then, calculates the possible fault locations based on the fault reactance and the electrical network model, and then shows the locations in seconds after the breaker trips. This really speeds up the isolation because without it, isolating even with remote disconnectors is much slower.” Thanks to this, the control room knows the possible fault location before even getting started with the remote isolation, and the field crew can be sent to the right place, faster.

The smoothness of automation also reaches customer communication.

Teemu describes: “When the outage is first created in the DMS, the system sends automated messages to the customers affected by the fault by SMS or email depending on individual preferences. After that, when we know the estimated restoration time, the operator sends another message to the customers that are still in the fault area, using DMS.” For that, the operator can easily use the DMS functionality to select what to add in the message - for example, the cause of the fault. “In the future, the idea in Elenia is that the field crews can do this from their UTG since they have the best information about how long it’s going to take to repair.”

Trimble software solutions provide situational awareness (SA) on multiple levels. Trimble DMS can be used to form SA understanding both on the utility level and for the control room operators. The mobile solution Utility To Go provides the situational understanding for the field crews.

In addition, Elenia’s customers get information about the outages via online outage map and the IVR (interactive voice response) system, both coupled the DMS. Teemu continues: “So if a customer calls to our outage hotline, the automated system tells if there is an ongoing outage in the caller’s zip code area, pulling the information automatically from the DMS.” The same information is published in Elenia’s online outage map, which shows the exact numbers and locations of the ongoing outages. “The online outage map is completely automated. It is really great for the customers, operators and the utility because the customers know the situation by checking the web, and the information is all updated automatically,” Teemu compliments.

Thanks to the smart services, out of all the customers who experience outages in the Elenia network, only 1,2% talk on the phone with the utility’s customer services. That equals with managing 98% (!) of all the customer communications with the online outage map, SMS, email, and IVR. In addition, the number of calls to the utility overall have reduced by approximately 50%, as the automated messaging reaches the customers before their need to contact the utility arises. “Our customers love getting information about the fault immediately when it starts and when it ends,” Teemu explains. “They don’t really need to contact people from the utility because they are fine with knowing that there is an outage but the network utility is aware of it and working on fixing it.”